Buying an X-ray inspection system is often worth it: food and pharma companies have reported annual savings of $80,000–$400,000 from reduced recalls, less waste, and improved efficiency, allowing many to recoup the machine cost within 1–2 years, making it a high-ROI investment.

Home / X ray inspection system

X-ray Inspection Systems: Advanced Solutions for Product Safety and Quality

Zero-Risk SafetyAI-Speed PrecisionFuture-Proof QC

Powered by advanced imaging algorithms, our X-ray inspection systems detect minute contaminants and structural defects, optimizing production efficiency and product integrity across food and pharma industries.

- Introduce

- Products

- Featured Products

- Support

- Cases

- FAQ

- Blog

AI-Driven Smart X-ray Inspection Systems for Ultimate Product Safety

X-ray inspection systems are non-destructive, highly reliable solutions for detecting foreign contaminants and verifying product integrity. Used across various industries—from food and beverage to pharmaceuticals and industrial components—our cutting-edge X-ray inspection machines deliver the precision and speed essential for modern production. These advanced X-ray inspection systems enhance operational efficiency and protect your brand by ensuring the highest product safety and quality. Explore our range of specialized X-ray inspection machines designed to meet your specific application needs.

- Non-destructive foreign object detection

- Maximize throughput with our X-ray Inspection Machines

- Minimize false rejects; maximize true detection

- Tailored X-ray Inspection System for your product

- Durable, efficient, and high return on investment

- Upgradeable AI ensures long-term quality control

Providing comprehensive X-ray inspection system solutions for food companies

X-ray Inspection Systems Application Scenarios

packaged food

Testing Applications:

√ Foreign Object Detection in Meat Products

√ Self-Heating Hot Pot Packaging Detection

√ Foreign Object Detection in Plastic Packaging

√ Aluminum Foil Packaging Sealing Detection

- Inspection Contents:

- Missing Item Detection

- Underweight Detection

- Seal Integrity Detection

- Foreign Object Detection (Metal, Glass, Ceramics)

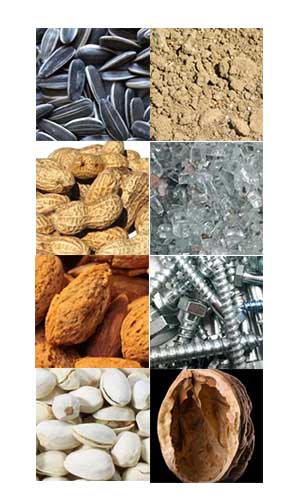

Bulk products

Applicable Products

√ Sunflower seeds, pistachios, peanuts

√ Beans, seeds, granular bulk feed

√ Dehydrated vegetables, tea, and Chinese medicinal herbs

√ Roasted nuts and other bulk products

- Detection Capabilities:

- Empty Fruit Detection ≥98%

- Damaged/Molded Fruit Detection

- Organic Impurity Sorting

- Foreign Object Detection (Metal, Glass, Ceramics, etc.)

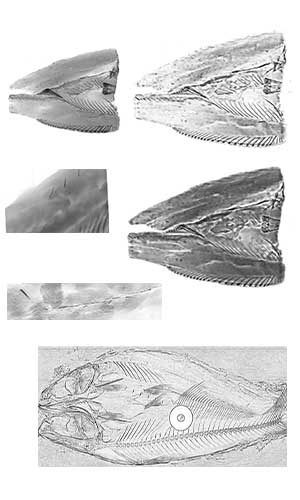

Aquatic products

Product Types

√ All kinds of fish products

√ Seafood

√ Fresh aquatic products

√ Special varieties such as basa fish

- Detection Accuracy:

- Can detect fish bones ≥0.2mm

- Ultra-high definition ≥0.05mm

- 4K high-definition display of details

- Dual-screen comparison display

X-ray Inspection Systems Product Group List

We offer a comprehensive portfolio of X-ray inspection systems, each tailored for specific applications and product types. Our commitment is to provide the best X-ray inspection machine for every unique requirement.

hot

Conveyor Belt Speed

10-60 m/min

Detector Resolution

0.4mm

Testing products

Packaged foods such as snacks, sauces, dairy products, and meat products.

hot

Conveyor Belt Speed

10-25m/min

Inspection Accuracy

Stainless steel wire 0.05*6mm

Max Printing Size

Fish bones, etc.

hot

Conveyor Belt Speed

10-60 m/min

Detector Resolution

0.2/0.4mm High-definition TDI

Testing products

Packaged foods such as snacks, sauces, dairy products, and meat products.

Get free

Get Your Free X-ray Inspection System Solution & Quote

Leave your contact information to receive the practical selection guide prepared by the SameGram technical team, including:

- Recommendations for X-ray inspection solutions across different food and packaging industries

- Key factors to consider when upgrading to X-ray detection

- ROI analysis for high-precision X-ray inspection systems

- Model selection tips for contaminants, such as metal, glass, bone, and plastics

- Guidance on choosing conveyor, rejection, and shielding configurations

What We Offer:

Your One-Stop X-ray Inspection System Service Partner

Expert Pre-Sales Consultation

Engage with our specialists for in-depth consultation. We analyze your specific production environment and quality challenges to recommend the ideal X-ray inspection machine solution.

Flexible Product Customization

Our engineering team provides extensive customization options. We modify our X-ray inspection systems to integrate with your existing lines and meet your exact, personalized requirements, from specialized software to unique hardware configurations.

Free Customized Solution Design

We offer a free, tailor-made X-ray inspection solution proposal, including detailed analysis and equipment recommendations, ensuring your system is perfectly optimized for your operational needs.

Comprehensive After-Sales Support

Our partnership continues with full-lifecycle support. This includes installation, training, maintenance, and rapid technical assistance to ensure your industrial X-ray inspection systems maintain peak performance, minimizing downtime and maximizing equipment lifespan.

Core Tech Advantages

Core Technology Advantages of the SameGram X-ray Inspection Systems

Real-Time Visual Inspection

Leading light source and high-resolution receiver with proprietary super-resolution algorithms for real-time, high-efficiency quality inspection on our X-ray inspection system.

Proprietary AI for Automated Inspection

Our automated X-ray inspection system utilizes proprietary neural networks (e.g., ZeroShot-SvDetector) for superior foreign object detection and advanced dual-energy imaging.

User-Friendly Software

The intuitive software interface eliminates complex settings, ensuring simple, stable, and reliable operation of the X-ray inspection system.

Robust Industrial Design

Each unit features a highly integrated, industrialized body with a high-computing power smart core, providing exceptional anti-interference capability for reliable industrial X-ray inspection.

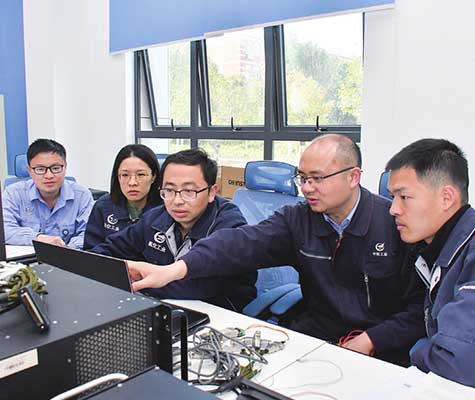

Specialized Team Expertise

With integrated R&D, production, and sales, we’ve built a strong sample and model library, enabling our food X-ray systems to quickly meet diverse and customized needs.

Related Cases

A leading seafood processor in Japan faced challenges with detecting small fish bones in fillets, which posed risks to product safety and consumer trust. After adopting the fish bone X-ray inspection system, including x-ray inspection machines for fish bones, the company achieved more accurate detection, reduced manual labor, and improved overall product quality. The system provided a reliable, automated solution that helped the customer meet food safety standards and maintain confidence in their products.

- Industry:

- seafood processing industry

- Equipment:

- fish bone X-ray inspection system

- Country:

- Japan

- Device model:

- XSS-F-4610

faq

Frequently Asked Questions

- Q:What is an X-ray inspection system and how does it work?

A:

Most X-ray inspection machines need a full technical inspection once a year to confirm calibration, detector stability, and radiation safety. In busy production lines, a quarterly performance check is recommended to keep sensitivity consistent. Routine daily checks of image quality, belt condition, and cleanliness help catch small issues early and prevent drift.

- Q:When should I use 3D/CT instead of 2D X-ray?

A:

Use 3D/CT for complex internal geometry, failure analysis, or precise metrology when 2D images aren’t sufficient.

- Q:Is investing in X-ray inspection worth it?

A:

- Q:In which industries can Samegram's X-ray inspection systems bse used?

A:

①primarily designed for the food industry, including:

Packaged foods (bottled or canned products)

-

- Bulk materials (grains, coffee, tea, and other loose products)

-

Seafood (fish fillets, fish bones, and fish spines)

②These systems can detect a wide range of foreign objects and contaminants, such as:

-

Metal fragments (iron, stainless steel, copper, etc.)

-

Glass shards

-

Stones or small rocks

-

Bones or bone fragments (e.g., fish bones)

-

High-density plastics or hard plastic pieces

-

- Q:How accurate are X-ray inspection systems?

A:

X-ray inspection systems are highly accurate, typically detecting contaminants as small as 0.5–1.0 mm, depending on product type, packaging, and system settings. Modern systems with dual-energy or AI-based image analysis can reliably distinguish between different materials (metal, glass, stone, bone, plastic) and reduce false rejects. Accuracy also depends on proper calibration, line speed, and operator maintenance.

- Q:Can the system be integrated with my production line?

A:

Yes, modern X-ray inspection systems are designed for production line integration. They can connect to PLC and MES systems, allowing automatic control, real-time data monitoring, and quality reporting. Most systems also support reject mechanisms to remove contaminated or defective products without stopping the line, ensuring efficient, continuous operation while maintaining high detection accuracy.

X-Ray Inspection System Knowledge Hub

Contact Us

Get solutions

Get free quotes

Quick response

- ISO/MID certified

- 100+ customers trust

- 1-on-1 engineer support

- ASK SameGram

- Contact SameGram

- Metal Detector Checkweigher Selection Table

- Checkweigher Selection Registration Form

- Labeling technical parameters

- Mobile Phone

- Mobile Phone

- Mobile Phone

- Mobile Phone

- Mobile Phone

- Product Finder

Quickly filter to find the product you want

- Inventory Machines

Short delivery time and quick installation

- Free Test Piece

Confirm after sensitivity test

- Customization Support

Inspiring customized solutions