Buying an X-ray inspection system is often worth it: food and pharma companies have reported annual savings of $80,000–$400,000 from reduced recalls, less waste, and improved efficiency, allowing many to recoup the machine cost within 1–2 years, making it a high-ROI investment.

Home / Metal Detection Solutions

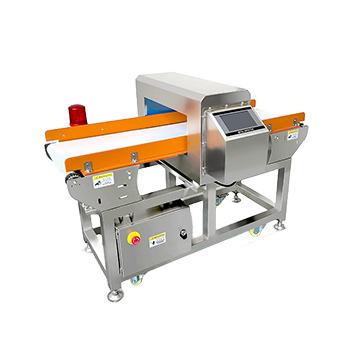

Conveyor Metal Detection Solutions

Detect and Remove Metal Contaminants to Ensure Product Safety, Compliance, and Brand Protection.

Even a tiny metal fragment in your product can spark safety scares, trigger recalls, and destroy brand trust overnight. In food and pharma, it’s not just a quality issue — it’s a legal, financial, and reputational crisis waiting to happen.

Global industries face strict purity regulations—HACCP, FDA, GMP, and more. For food and pharma manufacturers, failing metal detection can mean fines, shutdowns, or lost licenses. Meeting these standards across every product is a major operational challenge.

Slow, inaccurate metal detection slows your line, drives up costs, and risks unsafe products reaching customers. Without high sensitivity, you face recalls and lost revenue. Balancing speed, accuracy, and cost is now every manufacturer’s biggest challenge.

Reliable Conveyor Metal Detection Solutions, for Safer, High-Quality Production in Automated Manufacturing Lines.

In today’s automated production environments, maintaining product quality and consumer safety is critical to business success. Yet metal contaminants—from machine wear, raw materials, or human error—can severely damage your brand and bottom line.SameGram offers advanced metal detection systems tailored to these challenges. Our solutions help you minimize risk, improve efficiency, and meet the world’s strictest compliance standards with confidence.

Backend Pipeline Metal Detection

In food processing and pharmaceutical industries, undetected metal contaminants in backend pipelines pose severe risks, compromising food safety, violating GFSI standards, and leading to costly recalls and brand damage. Traditional industrial metal detectors often lack the precision and adaptability needed for diverse products, increasing false positives and inefficiencies.

Our industrial metal detector conveyor leverages advanced digital signal processing and a user-friendly touch screen interface to deliver high-sensitivity detection (FE ≥0.6mm, SUS304 ≥1.2mm) across food grade metal detectors and pharmaceutical metal detectors. With IP67-rated waterproof and shockproof design, customizable frequencies, and data storage for 100+ products, it ensures compliance with HACCP and FSMA, reducing waste and enhancing metal detection for food industry reliability.

skip to product

Superior Detection Technology

Our industrial metal detector systems excel in metal detector in food applications, using dual-frequency magnetic field detection and digital signal processing to achieve high sensitivity (FE ≥0.5mm, SUS304 ≥1.0mm) for various packaging products. Self-learning algorithms and automatic balance compensation eliminate interference from high-salt or moist products, ensuring precision in conveyor metal detectors. With IP66/IP67-rated 304 stainless steel builds, they meet HACCP and GFSI standards, thriving in demanding environments.

High-frequency detection enhances accuracy across ferrous and non-ferrous metals, supported by variable belt speeds (1–1000m/min) and rejection mechanisms like air blow or pushrod. The 7-inch LCD interfaces offer 100+ product memory and USB data export, ensuring traceability and simplified maintenance. These features make our detectors ideal for pharmaceutical and food industries, delivering robust, efficient performance in harsh conditions.

contact us

Aluminum Foil Packaging Metal Detection

Metal contamination in aluminum foil packaging is a critical issue for the food industry and pharmaceuticals, as standard conveyor metal detectors often fail due to foil interference, risking food safety, regulatory non-compliance, and costly recalls.

Our conveyor belt metal detector uses advanced DC multi-coil detection technology to accurately detect ferrous contaminants in food metal detector applications. With a compact, IFS/HACCP-compliant design, it integrates seamlessly into metal detector conveyor systems, offering high sensitivity, multiple rejection options, and a competitive conveyor belt metal detector price to ensure food grade metal detector standards.

Compliant products

Integrated Checkweigher Detection

Balancing weight accuracy and metal contaminant detection across food processing, pharmaceutical, textile, and chemical industries poses challenges for production lines. Our checkweigher and metal detector systems integrate seamlessly, combining both functions into a compact, modular solution that simplifies compliance with industry standards while reducing equipment costs and space requirements.

This integrated design delivers:

Unified Operation: Single-point control streamlines monitoring, minimizing operator training.

Space Efficiency: Compact footprint optimizes production floor space.

Enhanced Compliance: Automated data logging ensures audit-ready traceability.

Versatile Application: Adapts to diverse products, from packaged foods to pharmaceuticals. By reducing complexity and boosting efficiency, our systems empower customers with reliable, cost-effective quality control across high-throughput environments.

Diverse Product Portfolio: Meeting Various Industry Needs

We provide comprehensive conveyor metal detection equipment to suit diverse production environments and product characteristics:

Aluminum Foil Pack Metal Detector

- Detects ferrous metals in foil-packed goods with high sensitivity industrial metal detector technology.

- Ensures food safety compliance using metal detector in food lines for final-stage inspection.

- Compact, modular food grade metal detector integrates easily into food processing metal detector systems.

Advanced Conveyor Belt Metal Detector

- Detects all metals via industrial metal detector conveyor with IP65 rating and automatic learning system.

- Hygienic belt conveyor metal detector ideal for food-grade metal detection in light packaged goods.

- Advanced industrial metal detectors with LCD display, auto product tracking, and HACCP/IFS compliance.

Gravity Fall Metal Separator

- Free-Fall Metal Separator precisely removes metals from powders and granules in real-time flow.

- Gravity free fall metal detector prevents contamination in bulk raw materials, ensuring HACCP and IFS compliance.

- Fully enclosed 304 stainless steel design meets food-grade hygiene and dust-proof processing standards.

End of Line Conveyor Metal Detector

- Food metal detectors ensure precise product detection with optimized sensitivity, no recalibration required.

- Metal detector for conveyor belt supports real-time parameter changes, data tracking, user access control.

- Conveyor metal detectors meet IP67, GFSI, and FSMA standards, reducing false rejects and production waste.

- conveyor metal detector

- industrial metal detector

- food metal detector

- high sensitivity metal detector

- waterproof metal detector

- metal detection system

- automatic metal detector

- inline metal detector

- multi-frequency metal detector

- metal detector for packaging line

- metal detector for food processing

- metal detection machine

- stainless steel metal detector

- metal detection equipment

- metal detector for pharmaceutical

- metal detector with rejector

- metal detection conveyor

- metal detector for plastic industry

- metal detector with data logging

- high speed metal detector

- metal detection sensor

- metal detector for quality control

- metal detector for bakery industry

- metal detector for nuts and snacks

- metal detector for textile industry

faq

Frequently Asked Questions

- Q:Can the system be integrated with my production line?X-ray inspection systems can be integrated with production lines, supporting PLC/MES control, automatic reject mechanisms, and data reporting for seamless quality control.

A:

Yes, modern X-ray inspection systems are designed for production line integration. They can connect to PLC and MES systems, allowing automatic control, real-time data monitoring, and quality reporting. Most systems also support reject mechanisms to remove contaminated or defective products without stopping the line, ensuring efficient, continuous operation while maintaining high detection accuracy.

- Q:How accurate are X-ray inspection systems?Accuracy depends on energy, detector, and algorithms; dual-energy and AI improve material discrimination and lower false positives.

A:

X-ray inspection systems are highly accurate, typically detecting contaminants as small as 0.5–1.0 mm, depending on product type, packaging, and system settings. Modern systems with dual-energy or AI-based image analysis can reliably distinguish between different materials (metal, glass, stone, bone, plastic) and reduce false rejects. Accuracy also depends on proper calibration, line speed, and operator maintenance.

- Q:In which industries can Samegram's X-ray inspection systems bse used?SameGram X-ray inspection systems are designed for the food industry, including packaged, bulk, and seafood products, and can detect contaminants such as metal, glass, stones, bones, and hard plastics, ensuring product safety and quality.

A:

①primarily designed for the food industry, including:

Packaged foods (bottled or canned products)

-

- Bulk materials (grains, coffee, tea, and other loose products)

-

Seafood (fish fillets, fish bones, and fish spines)

②These systems can detect a wide range of foreign objects and contaminants, such as:

-

Metal fragments (iron, stainless steel, copper, etc.)

-

Glass shards

-

Stones or small rocks

-

Bones or bone fragments (e.g., fish bones)

-

High-density plastics or hard plastic pieces

-

- Q:Is investing in X-ray inspection worth it?X-ray inspection systems quickly pay for themselves by reducing recalls, cutting waste, and improving efficiency, delivering a strong ROI for food, pharma, and electronics manufacturers.

A:

- Q:When should I use 3D/CT instead of 2D X-ray?Use 3D/CT for complex internal geometry, failure analysis, or precise metrology when 2D images aren’t sufficient.

A:

Use 3D/CT for complex internal geometry, failure analysis, or precise metrology when 2D images aren’t sufficient.

- Q:What is an X-ray inspection system and how does it work?X-ray inspection machines should receive an annual technical inspection, with quarterly checks for high-volume lines, while daily basic checks help maintain stable performance and prevent issues.

A:

Most X-ray inspection machines need a full technical inspection once a year to confirm calibration, detector stability, and radiation safety. In busy production lines, a quarterly performance check is recommended to keep sensitivity consistent. Routine daily checks of image quality, belt condition, and cleanliness help catch small issues early and prevent drift.

Ready to Build Your Own Solution?

Contact us today to design a checkweighing and inspection system that fits perfectly—because your production needs to be accurate to every gram.

Choosing SameGram means

Flexible customization

Perfectly adapt to existing systems

Rich experience

16 years of professional manufacturing precipitation

Free samples

Support remote viewing and sample testing

Fast delivery

standard products in stock, shipped on the same day

Extensive verification

5000+ customers trust, wide industry coverage

After-sales guarantee

2-year warranty, lifetime maintenance

- ASK SameGram

- Contact SameGram

- Metal Detector Checkweigher Selection Table

- Checkweigher Selection Registration Form

- Labeling technical parameters

- Mobile Phone

- Mobile Phone

- Mobile Phone

- Mobile Phone

- Mobile Phone

- Product Finder

Quickly filter to find the product you want

- Inventory Machines

Short delivery time and quick installation

- Free Test Piece

Confirm after sensitivity test

- Customization Support

Inspiring customized solutions