Ultimate Guide to Checkweigher with Metal Detector Systems for Enhanced Food Safety

In today's fast-paced food production environment, ensuring every product meets strict quality standards is non-negotiable. That's where a checkweigher with metal detector comes into play—a powerful, integrated system designed to verify product weight while simultaneously scanning for metal contaminants. This combination not only streamlines operations but also safeguards consumer health by preventing underweight or contaminated items from reaching the market.

At SameGram, we've been at the forefront of manufacturing high-precision weighing and detection solutions for over a decade. As a leading provider based in China, our factory specializes in customizable systems that integrate seamlessly into production lines. Whether you're in food processing, pharmaceuticals, or packaging, our combination metal detector and checkweigher systems are engineered to boost efficiency and compliance. Explore Our Full Range of Checkweigher Systems on our Homepage, or dive into the details of our Combination Checkweigher with Metal Detector to see how we craft these innovative tools.

In this guide, we'll break down everything you need to know about these systems, from their core functions to real-world applications. By the end, you'll understand how implementing a checkweigher and metal detector can solve common production challenges like weight inaccuracies and foreign object risks.

What Is a Checkweigher with Metal Detector?

A checkweigher with metal detector is a dual-function machine that combines dynamic weighing technology with advanced metal detection capabilities. The checkweigher system component ensures products meet exact weight specifications—critical for regulatory compliance and cost control—while the food metal detector scans for ferrous, non-ferrous, and stainless steel contaminants that could pose safety hazards.

Imagine a conveyor belt where items like packaged snacks or bottled beverages pass through at high speeds. The system weighs each one in motion (known as in-motion checkweighing) and flags any deviations. Simultaneously, it uses electromagnetic fields to detect metal fragments as small as 0.5mm, depending on the setup. If an issue arises, an automatic rejector—such as a pneumatic pusher or flipper—removes the faulty product without halting the line.

This integration addresses key pain points in food safety: overfilling wastes resources, underfilling leads to customer complaints and fines, and contaminants can trigger recalls. Our SameGram automatic checkweigher metal detector model, like the SCM-4530L2 Automatic Checkweigher & Metal Detector, exemplifies this with its precision weighing up to ±0.1g and detection sensitivity that meets HACCP standards. For more specs, check our product page.

Key Benefits of Checkweigher with Metal Detector Systems

Investing in a combination metal detector and checkweigher systems offers tangible advantages that go beyond basic compliance. Here's why manufacturers are turning to these solutions:

1. Space and Cost Efficiency: By merging two functions into one unit, you save valuable floor space and reduce equipment costs. No need for separate machines—our systems at SameGram are compact yet robust, ideal for tight production areas.

2. Enhanced Food Safety and Compliance: These systems align with global standards like FDA and EU regulations. The metal detection prevents hazards from metal shards (e.g., from machinery wear), while checkweighing ensures accurate portions, supporting HACCP and food checkweighing protocols.

3. Improved Operational Efficiency: With speeds up to 300 items per minute, downtime is minimized. Features like automatic rejection and data logging help track trends, reducing waste by up to 20% through precise feedback to upstream fillers.

4. Versatility Across Products: Handle everything from dry goods to wet environments. Our checkweigher metal detector units feature IP65-rated enclosures for washdown resistance, making them suitable for harsh conditions.

5. Data-Driven Insights: Integrated software provides real-time reports on weights, rejections, and detections. This helps in predictive maintenance and quality audits, turning potential problems into proactive fixes.

For businesses facing recalls or inefficiencies, these benefits translate to real savings. One of our clients in the snack industry reported a 15% drop in overfill losses after installing our metal detector checkweigher system. Learn more about our tailored solutions in various industries on our Checkweigher with Metal Detector Industry Applications Page.

How Dynamic Checkweigher with Metal Detector Systems Work

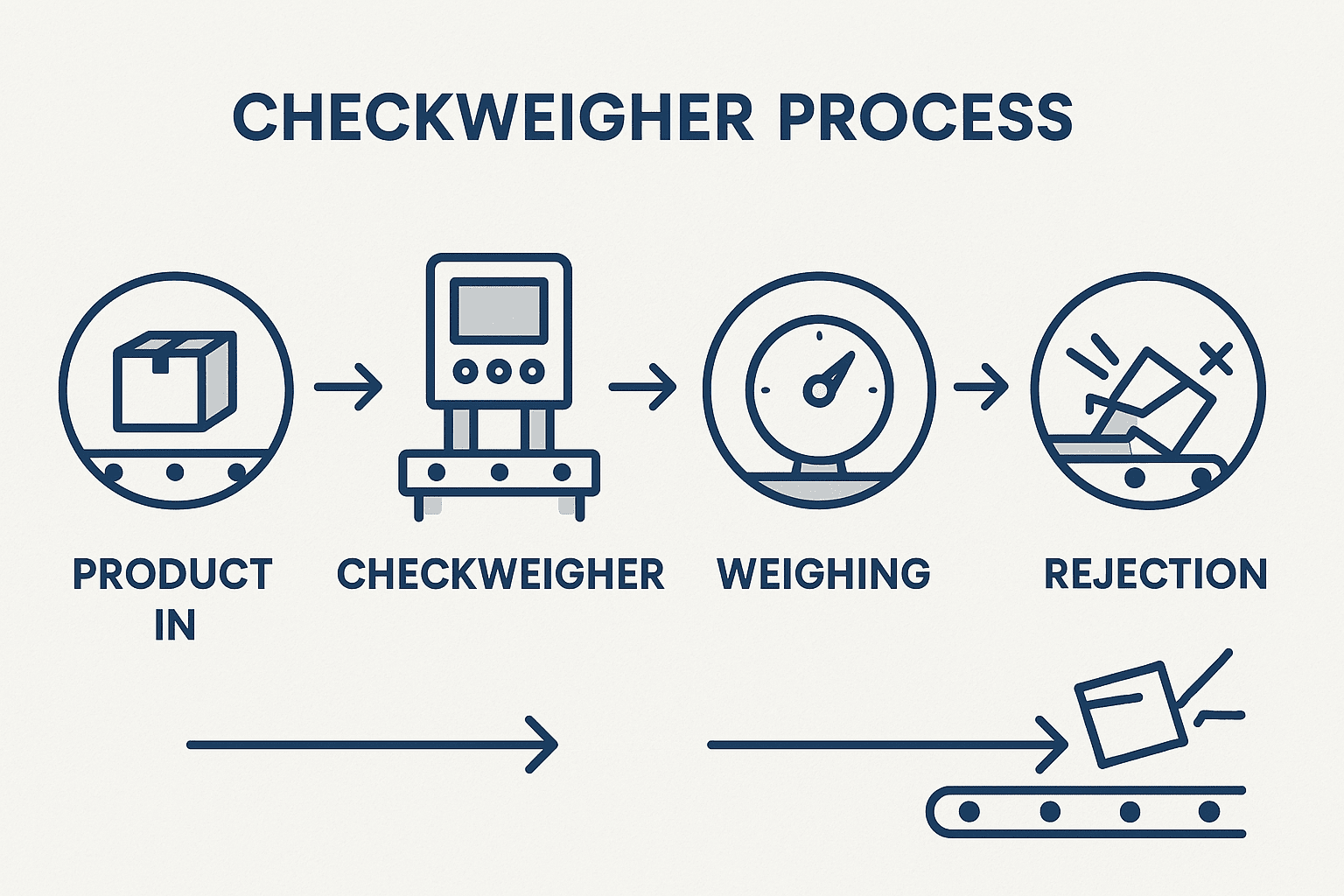

Understanding the mechanics demystifies why these systems are so effective. Let's break it down step by step.

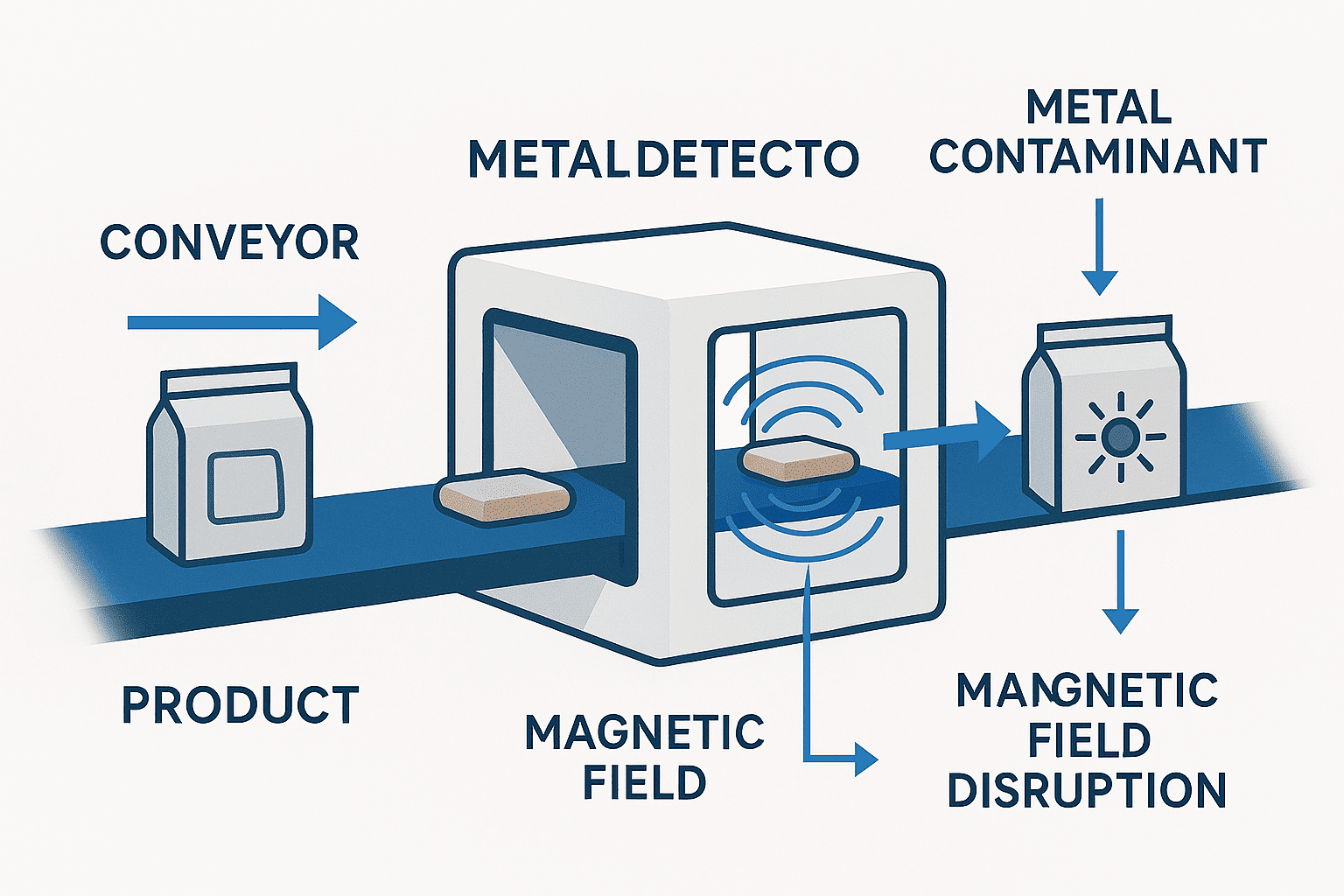

The process starts with the conveyor system, often a metal detector conveyor system also know as conveyor metal detector, feeding products into the unit. As items enter the metal detection zone, coils generate an electromagnetic field. Any metal disrupts this field, triggering an alert. Sensitivity can be adjusted for product types—e.g., higher for conductive items like salty snacks.

Next, the dynamic checkweigher takes over. Using load cells and advanced algorithms, it weighs products in motion without stopping the line. Our SameGram models achieve ultra-fast response times, ensuring accuracy even at high throughputs. If a product is underweight, overweight, or contaminated, the rejector activates—options include air blasts for lightweight items or pushers for heavier ones.

Key components include:

● Sensors: High-precision for both weight and metal.

● Control Interface: User-friendly touchscreens for easy setup.

● Integration: Compatible with upstream/downstream equipment like fillers or labelers.

Troubleshooting common issues? If false rejections occur, calibrate sensitivity or check for vibrations. Our systems come with built-in diagnostics to simplify this. For a deeper dive, visit our High-Precision Checkweigher Page for technical details.

Industry Applications: Where Dynamic Checkweigher with Metal Detector Systems Shine

Checkweigher with conveyor metal detector systems are versatile, but they excel in sectors where safety and precision are paramount.

● Food Industry: In food metal detectors and food checkweigher setups, they prevent contaminants in baked goods, meats, or dairy. For instance, our systems ensure uniform weights in packaged meals while detecting metal from processing equipment.

● Pharmaceuticals: Pharma checkweigher applications verify tablet or capsule weights and scan for metal impurities, complying with GMP standards.

● Packaging and Logistics: For checkweigher for packaged food or case checkweigher system, they confirm box weights and detect foreign objects, reducing shipping errors.

In a real scenario, a beverage producer used our conveyor belt metal detector integrated with checkweighing to catch underfilled bottles contaminated by metal caps—averting a potential recall. Explore Our Weighing, Metal Detecting, and Labeling Solutions for Specific Industries to see case studies.

Choosing the Right Checkweigher with Metal Detector System

Sample Content

Selecting the ideal system involves evaluating your needs:

● Throughput and Speed: Match line speeds; our models handle up to 200 packs/min.

● Sensitivity and Accuracy: Look for adjustable detection levels and weight precision like ±0.5g.

● Environment: Opt for washdown checkweigher if in wet areas.

● Integration and Customization: Ensure compatibility with existing lines; SameGram offers OEM customization.

● Support and Maintenance: Choose providers with robust after-sales, like our validation and calibration services.

Budget-wise, entry-level systems start around $10,000, but ROI comes quickly through waste reduction. Consult our experts at SameGram for a free assessment—Contact Us.

Conclusion: Elevate Your Food Safety Today

A checkweigher with metal detector isn't just equipment—it's a safeguard for your brand's reputation and bottom line. By combining food metal detection systems with precise weighing, you achieve compliance, efficiency, and peace of mind.

At SameGram, we're committed to delivering top-tier solutions from our state-of-the-art factory. With years of expertise, we help clients worldwide optimize their lines. Ready to upgrade? Visit Our Weighing, Metal Detecting, and Labeling Product Listings or reach out for a customized quote. Let's ensure your products are safe, accurate, and ready for the market.